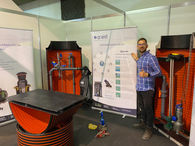

Vacuum drainage wells

Plastic manholes are designed to connect the property to the centralized vacuum sewer system. Currently, vacuum sewer systems have been built in Latvia in Jaunolaine, Pārolaine, Baltezera and a separate district of Mārupe. We make wells to order, we can embed additions to the well in the required angles and depths.

Application of vacuum sewer wells

-

For an existing system connecting a new consumer

-

New systems in the construction process

-

Lightweight polyethylene (PE100) construction

-

Easy to install in the ground, no heavy machinery required

-

Resistant to high groundwater conditions, self-anchoring base part

-

Easy-to-reach valve and easy-to-open contour line

-

Large working volume for waste water collection

-

Multiple connections, to varying degrees

-

Large free lid opening 600mm

-

Durable double wall housing

-

Industrially made

-

Inner diameter 800mm

-

Installation depth on request

-

Green zone PE cover for load up to 3.5T

-

Undercarriage cover for load up to 40T

-

Casing roundness resistance SN2, 2kN/m2

Advantages of vacuum sewer wells

Vacuum well equipment

Wells are equipped with 63mm or 90mmautomatic vacuum valve, which is powered bysystem vacuum and activatesfloat mechanism, as soon as the set well filling is reached - the valve opens, the contents of the well are pumped into the system, and at the end of the cycle, the system vacuum closes the valve and seals the system to prevent air from entering it.

Advantages of the valve:flow rate up to 250 l/min, Certified according to EN1091, made of high quality materials (SS316, EPDM, POM, PVC), Each valve tested before delivery, Works also in fully submerged condition, Patented air/water ratio that allows to reduce the power of vacuum pumps , Warranty 20,000 cycles, or lifetime warranty.

Vacuum wells are designed so that their maintenance is convenient and safe

-

The internal equipment is designed withcontour line, if the well is full and the valve has not worked, it is possible to empty the well by opening the bypass valve, which is located in the upper part of the well, thus easily accessible.

-

The float mechanism is easily removed by loosening onebolt, as well as the vacuum valve itself can be reached from the surface of the earth, therefore there is no need to climb into our vacuum wells even in the worst conditions and scenarios, although the large internal diameter of 800mm provides such an opportunity.

-

The wells are large enough to accommodatefor collecting wastewater (buffer tank) at least for one day, so consumers connected to the system can safely use the utility services in cases where the system is not working, because the internal equipment of the wells can be completely underwater and it will work perfectly.

Vacuum wells

-

The working volume of the well is 150 l

-

The total volume of the tank is 600 l

-

Made of high quality materials (PEHD, PVC)

-

In case of flooding, no additional actions are required

-

A highly reliable pneumatic/mechanical level control device

-

Automatic restoration of the air/water ratio in case of system shutdown for a longer period of time.

-

Self-anchoring, with concrete filling at the base of the well, which protects mechanisms from the influence of groundwater pressure.